-

Strategies built around you.

We proudly offer consultation without cost, whilst taking the time to understand your objectives and provide personalised recommendations that offer a fresh perspective.

Our approach is centred on collaboration, working in partnership with our clients to achieve measurable success, which allows your business to continuously grow and evolve.

As market-leading innovators, we are committed to introducing cutting-edge solutions and providing clarity on what the latest options are during the initial planning phase.

-

Expertise to resolve every challenge.

Our regional project development managers are highly knowledgeable and experienced in various industries, including pharmaceutical, food, environmental, and research & development.

Their expertise is critical in project development as it enables them to comprehend the unique challenges and opportunities of your industry. This understanding allows them to solve problems effectively, generate innovative solutions, and build lasting relationships within the industry.

-

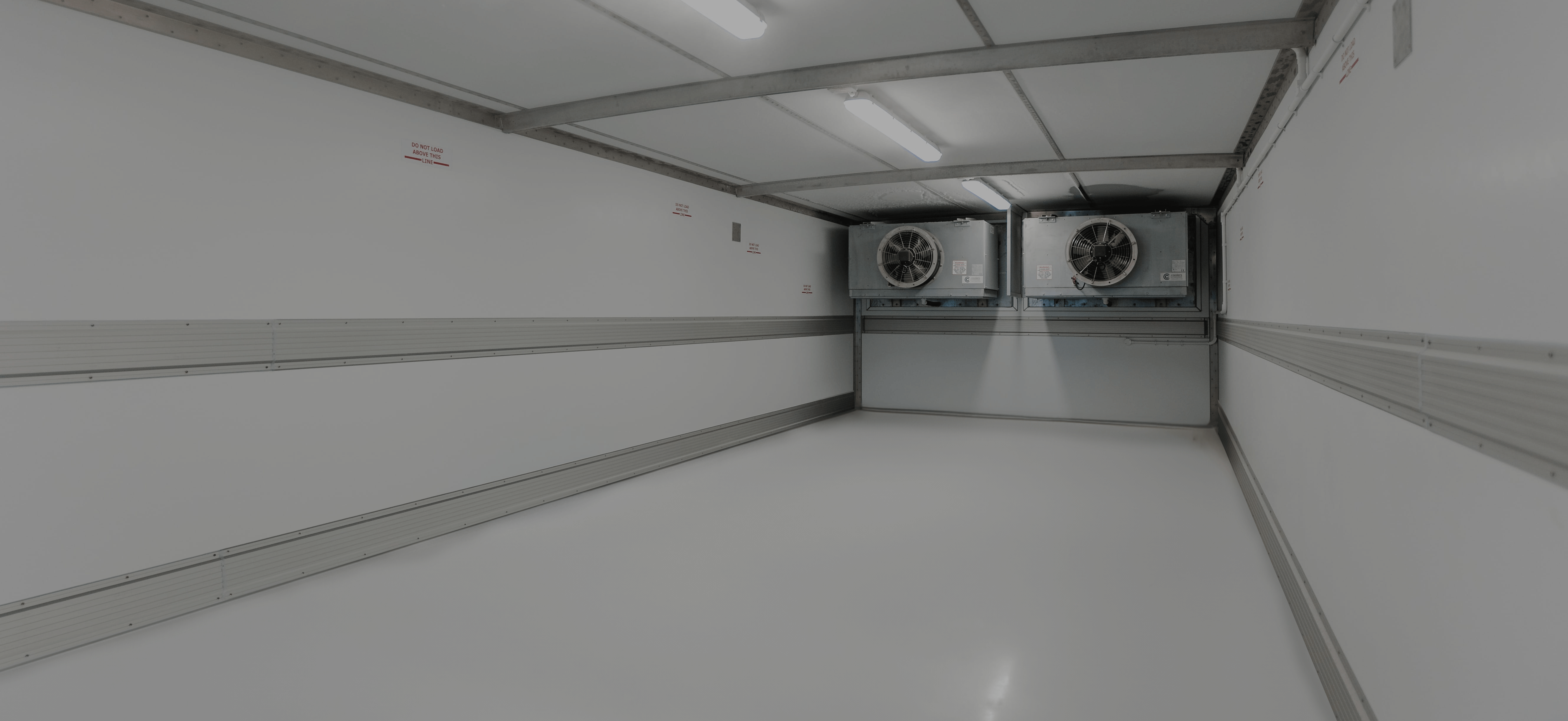

Temperature control made easy.

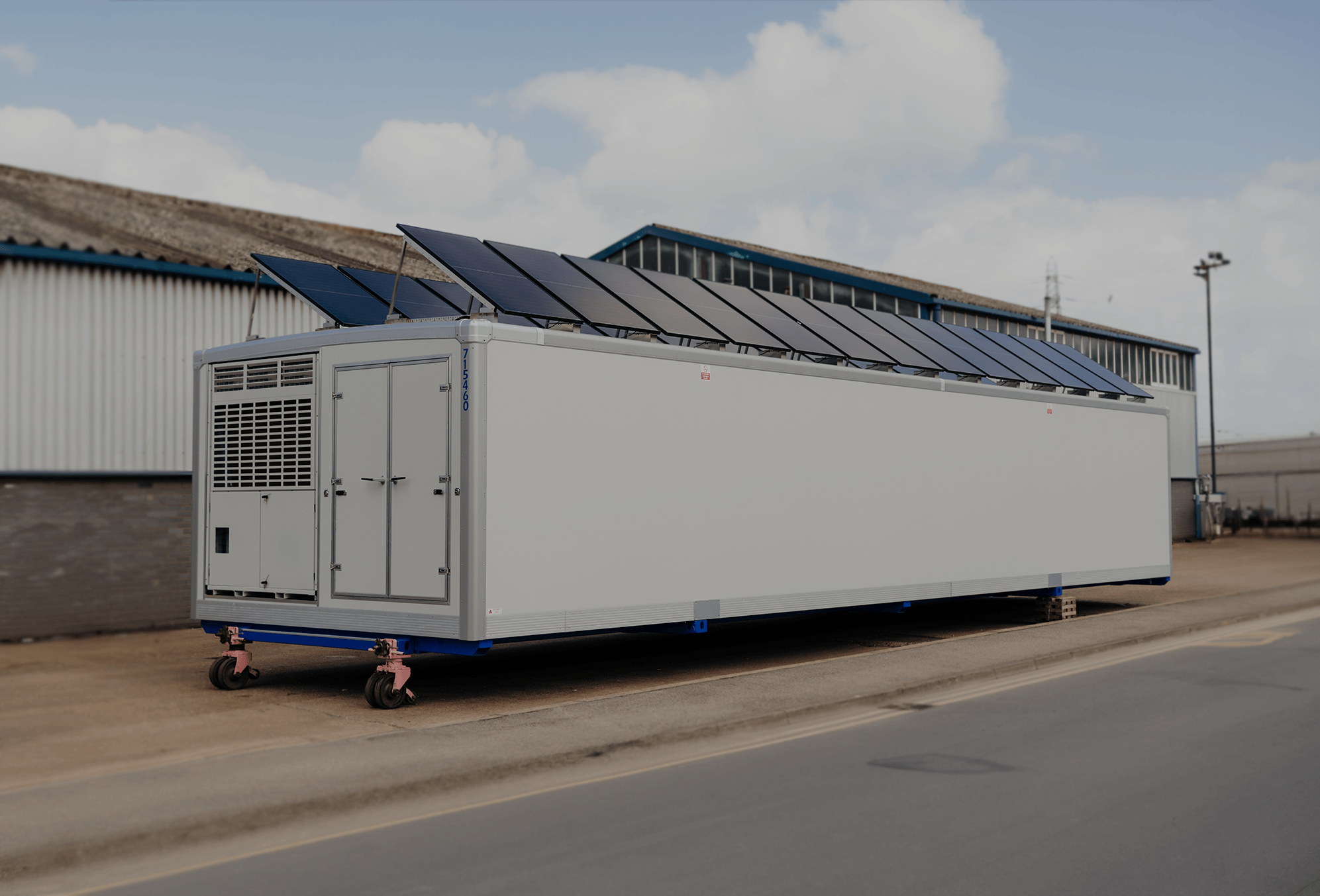

Dawsongroup TCS provides personalised temperature control solutions using a wide range of products and services, such as blast freezers and chillers, warming rooms, modular complexes, inflatable structures, production facilities, loading docks, clean rooms, and more.

Partner with Dawsongroup TCS for cutting-edge, tailored temperature control solutions that enhance quality and cost-effectiveness. Boost your business efficiency and enjoy peace of mind. Learn more now.

-

Over 30 Years of Experience …

We have 30 years experience working with the Food and Drink, Pharmaceutical, Logistics, Research and Development and Environmental industries; providing each with solutions that improve their processes, efficiency and productivity.

-

Enquire today.

Enquire today for the latest temperature control solutions. Fill out the form below to send your inquiries and receive comprehensive assistance from our team.

Modular Cleanrooms

Create Controlled Environments with Modular Cleanrooms. Learn more.

View Modular Cleanrooms.Production Facilities

Expand your production capabilities without compromising quality or efficiency. Explore our modular cleanroom solutions today.

View Production Facilities.Modular Complexes

Embrace the future of construction with modular complexes. Experience the benefits of a permanent build without the extended timelines and disruptions of traditional methods.

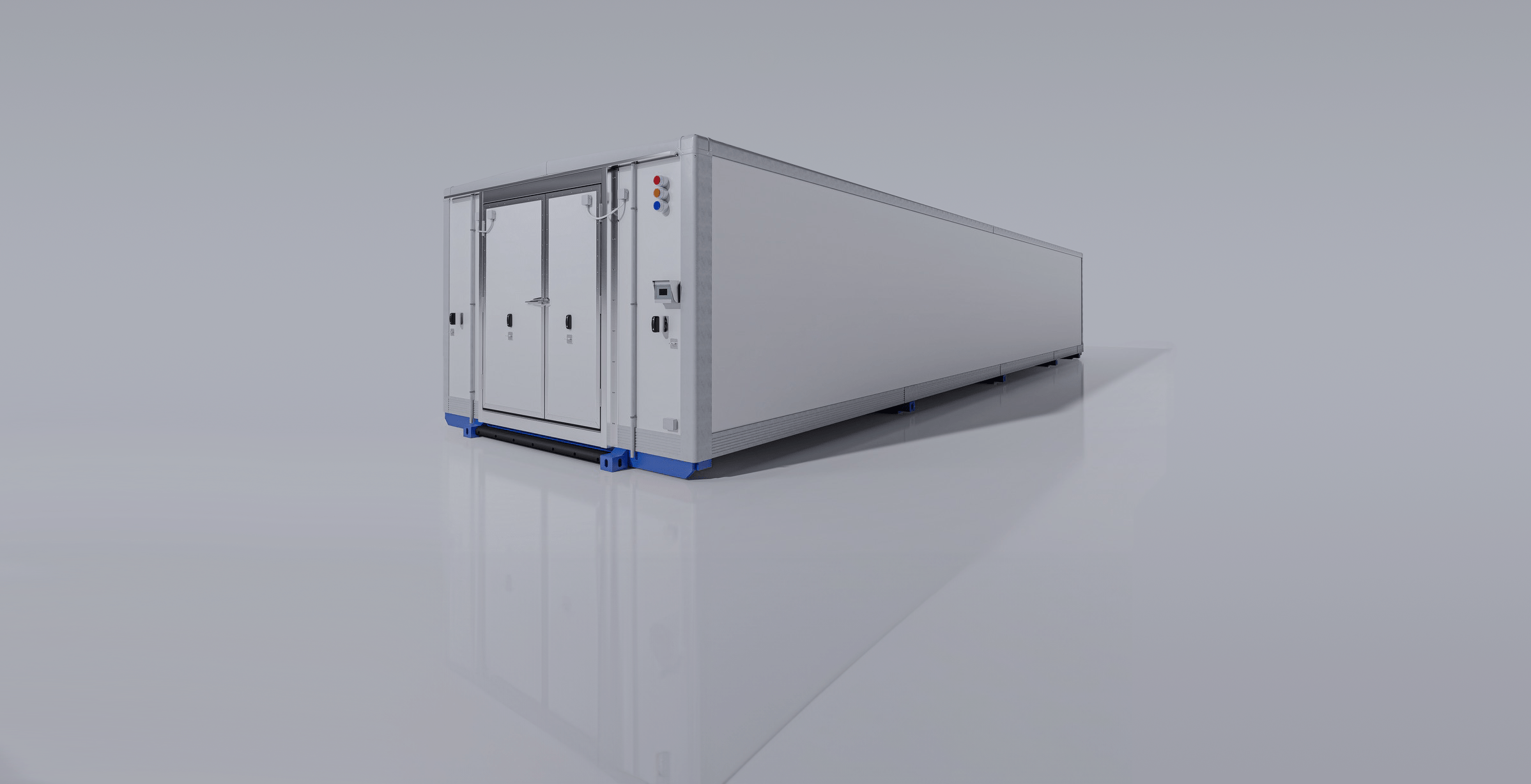

View Modular Complexes.Blast Freezers & Chillers

Achieve your Net Zero and Sustainability goals while enhancing your blast chilling and freezing operations. Contact us today to explore our solutions.

View Blast Freezers & Chillers.Dawsongroup Build

Partner with Dawsongroup Build for customised cold storage solutions that meet your unique needs. Enquire today.

View Dawsongroup BuildInflatable Cold Stores

Unleash the power of inflatable technology with our cutting-edge cold stores. Find out more.

View Inflatable Cold StoresCold Stores – Chill & Freeze

Never compromise on cold storage again. Our modular cold stores offer flexible, scalable solutions for all your chiller and freezer needs.

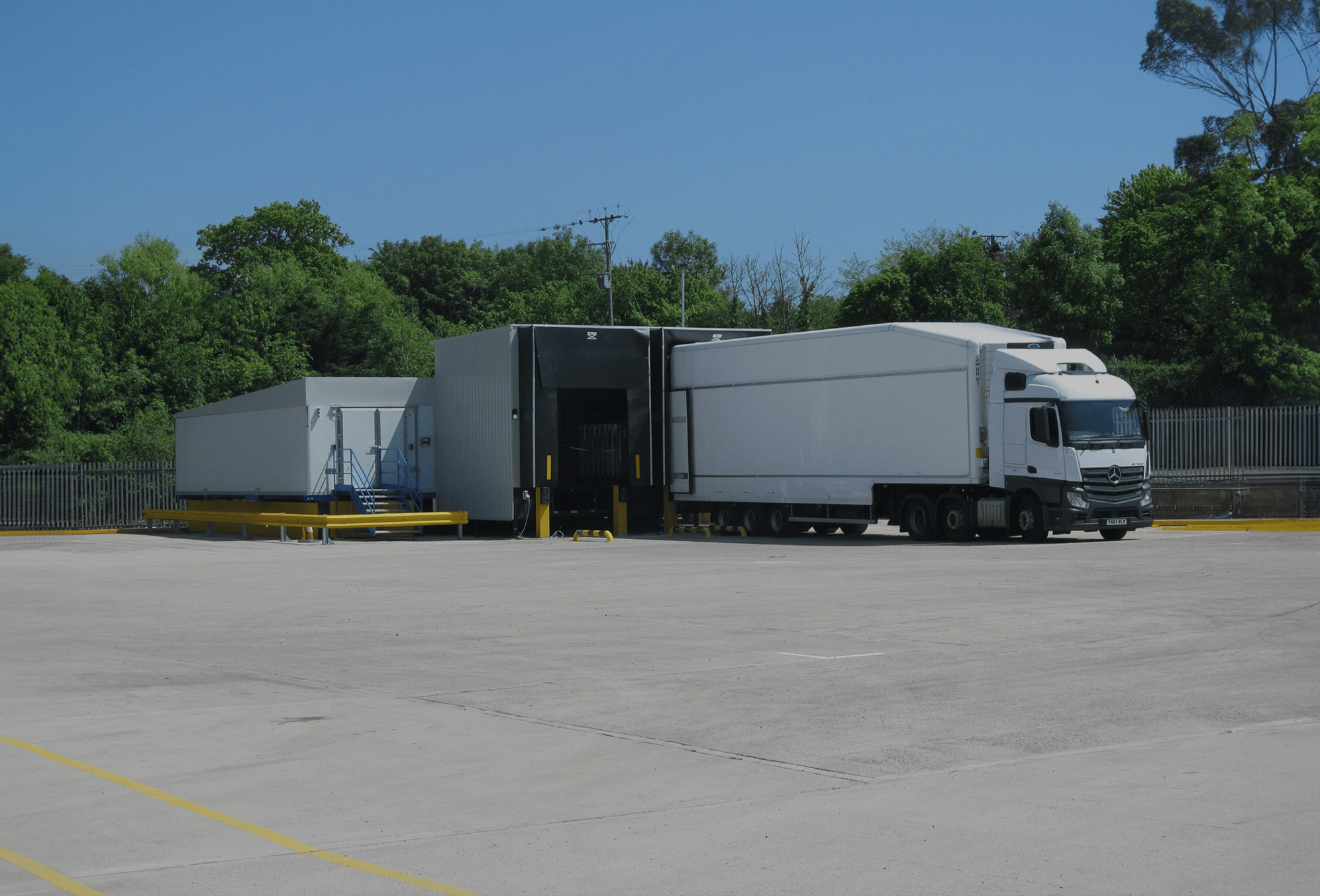

View Cold StoresDock Loading Pods

Optimise your loading dock operations with our modular loading dock solutions. Contact us today for a free consultation.

View Dock Loading PodsTemperature Control Solutions

Dawsongroup Temperature Control Solutions (DGTCS), as the name suggests, offers temperature control solutions for businesses across a range of industry sectors.

These solutions incorporate the best range of equipment and options available in the market, a consequence of 30 years of experience and working with the right partners. But, much more importantly, we put our customers’ business first which is what makes DGTCS number one in the market.

Question one is always ‘What are you trying to achieve?’ Our primary aim is to ensure our solution improves your business, so whatever we supply must fit your process flow.

We provide what you need whether internal, external or bespoke to your exact requirements and the internal support team will look after the entire process from design and project management to completion. At this point, we hand over your project to our customer services team to ensure your complete satisfaction.

Contact us to book a free consultation or call our team on 01623 518538.

Industries We Support

Talk to us about your project…

To get in touch directly, please use the following details.

-

Dawsongroup temperature control solutions,

Export Drive,

Sutton-in-Ashfield,

Nottinghamshire,

NG17 6AF

Leave an enquiry, please use the form below and we’ll get back to you shortly.

Latest News

Dawsongroup Temperature Control Solutions brings precision to temperature control across diverse industries, from pharmaceuticals and food processing to aerospace and electronics manufacturing. Leverage our expertise and innovative solutions to ensure your temperature-sensitive products and processes are in expert hands.

Celebrating Success at the Festival Supplier Awards 2024

The Festival Supplier Awards 2024 was a spectacular event. Held at the Hurlingham Club, London, it celebrated outdoor events and all the fantastic suppliers and production teams who deliver ...

Supermarkets to Reintroduce Charges Over Breaches in Delivery Standards

A recent article published in The Grocer has announced the intentions of one high-end supermarket chain to reintroduce penalty charges for suppliers that breach their delivery standards. These standards ...

Dawsongroup tcs shortlisted for Festival Supplier Awards 2024

Dawsongroup tcs has today announced that they are finalists in the prestigious Festival Supplier Awards 2024. The company is shortlisted in the Best Plant & Equipment Hire, Best Support ...

Beat the Supply Chain Strain

With 2024 just around the corner, it’s time for businesses to start planning for the opportunities that lie ahead. However, the new year can represent a level of uncertainty, ...

Celebrating Innovation and Excellence: Proud Sponsors of the Pharma Industry Awards UK 2023

The Pharma Industry Awards have been a beacon of excellence in the pharmaceutical sector since launching in 2014. The awards bring together industry leaders, innovators and visionaries who are ...

Embracing the Increased Demand for Frozen Food

In recent years, demand for convenient, high-quality meal options has skyrocketed, and frozen food manufacturers are reaping the rewards. Independent research, commissioned by the British Frozen Food Federation (BFFF), ...

National Veterinary Services: New State-Of-The-Art Warehouse & Distribution Facility

In the ever-evolving world of pharmaceutical distribution and logistics, innovation is essential in order to keep up with customer demand and ensure regulatory compliance. National Veterinary Services (NVS), a ...

Flexible Cold Storage Solutions to Keep Up With Seasonal Demand

Seasonal variations in consumer demand can cause a significant issue for supply chains, especially in the lead-up to Christmas. In order to keep up with seasonal demand, your business ...

Bringing the Big Picture to RTX2023

The Road Transport Expo returned to NAEC Stoneleigh in the last week of June for its second successful year. More than 200 exhibitors and thousands of visitors from different ...

Working Together Towards a Smarter Asset Strategy

Dawsongroup’s supersite at Avonmouth – the first of its kind – embodies our aim of working together towards a Smarter Asset Strategy. Whilst other depots usually have one or ...